Solar panel technology

In 2018, 94,000 MW of new photovoltaic solar generation capacity were added worldwide , representing 55% of the total new renewable energy generation capacity in that year. Altogether, there are almost 500,000 MW of installed photovoltaic electrical power. Solar energy is already the preferred electricity production technology worldwide, mainly because the cost of electricity produced with photovoltaic solar energy has been falling steadily in recent years. Between 2010 and 2018 there was a 77% decrease in average costof the photovoltaic energy produced (LCOE, Levelized Cost of Energy). In 2018 alone, the LCOE fell by 13%, supported by a decrease in the prices of the crystalline silicon module close to 30%.

Photovoltaic solar cells and panels

When talking about photovoltaic technology, it is necessary to distinguish between cells and solar modules or panels. Thus, the basic element is the photovoltaic cell, a semiconductor device that allows the energy of sunlight to be transformed into electrical energy through the photoelectric effect. Solar panels are made up of arrays of photovoltaic cells. The families of semiconductors for photovoltaic generation are classified as:

Silicon wafer- based photovoltaic technology represented approximately 95% of total production in 2017, mostly polycrystalline cells.

How they are made

Monocrystalline silicon photovoltaic cells are made from silicon wafers that are cut from single crystal silicon cylindrical ingots. Due to the required manufacturing processes, it is the most expensive type of silicon cell. In contrast, polycrystalline or multi-crystalline silicon photovoltaic cells are made from blocks of molten, cooled and solidified silicon, using a cheaper manufacturing process that produces less energy efficient cells. Amorphous silicon cells were the first thin-film cells to be marketed but they have been falling behind in the market before crystalline silicon cells.

The panels are built by joining the silicon photovoltaic cells. The cell connection in parallel is used to increase the total current produced while the series connection is used to increase the voltage. In front, a glass protects the cells, and behind they are glued on a substrate.

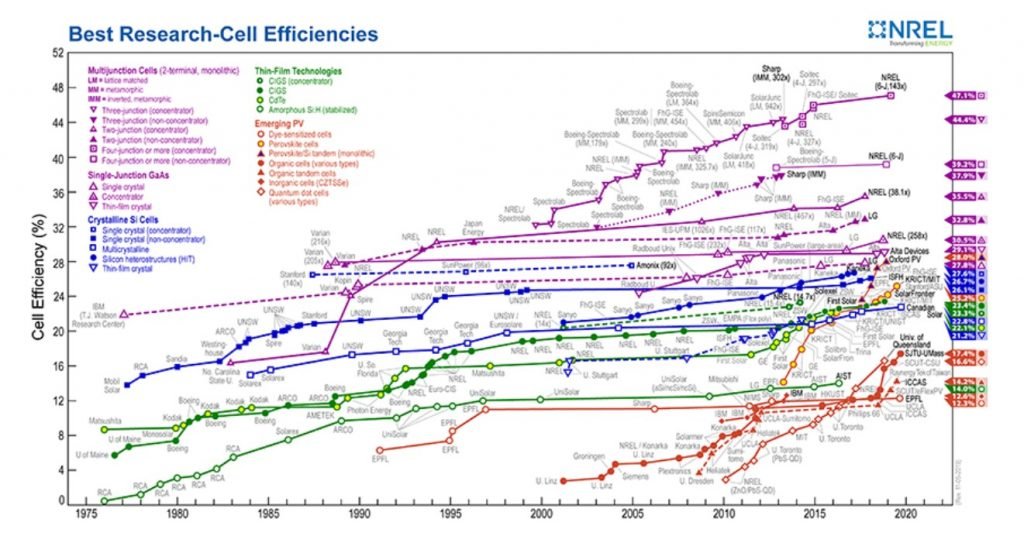

Energy efficiency records

In recent years, the records of efficiency in energy production have been broken annually through the different photovoltaic technologies. Thus, the record efficiency of the laboratory cell is 26.7% for monocrystalline technology and 22.3% for technology based on polycrystalline silicon wafers. The highest laboratory efficiency in thin film technology is 23.4% for CIGS and 21.0% for CdTe solar cells.

This has helped to also improve the efficiency of the solar modules or panels made from these photovoltaic cells. In the last 10 years, the efficiency of commercial wafer-based silicon modules has increased from approximately 12% to 17%. At the same time, the efficiency of the CdTe modules has increased from 9% to 18%. On the other hand, the amount of material required has been significantly reduced, going in recent years from 16 g / Wp (grams of silicon per Watt-peak) to approximately 4 g / Wp, due to the higher efficiency of the cells but also to the availability of finer wafers.

Hybrid solar panels

One of the most promising emerging technologies is the hybrid solar panel, which is capable of producing electricity and hot water simultaneously from solar energy. It consists of a photovoltaic system for the production of electricity and a hydraulic system for the production of hot water, which minimizes energy losses and maximizes photovoltaic production by reducing the temperature of the panel. This solution allows the integration of two technologies in a single panel, satisfying in a more efficient way the electrical and thermal energy consumption of buildings.