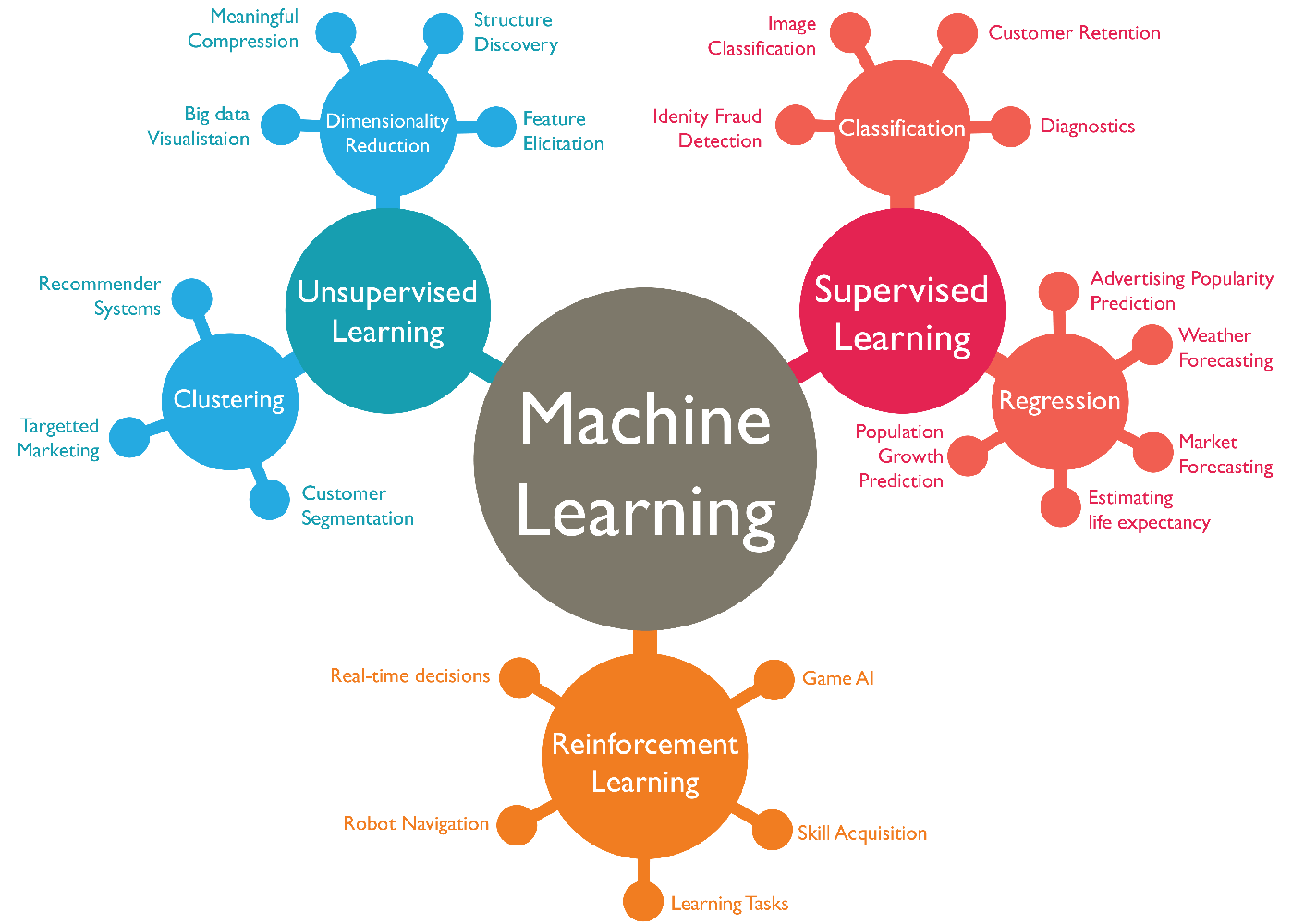

What Is Machine Learning In Manufacturing

Enterprise cloud technology contributes considerably to ushering in an era of incredible growth. What is less apparent is how manufacturing or the automotive industry will benefit from the public cloud. Products, processes, and machines are being developed to create intelligent factories.

Of course, data is also the focus here. Data can be used as part of machine learning ( ML ) for machine vision or predictive maintenance, but also to make strategic business decisions and answer previously unanswered questions, such as B. “Which machines perform best?”, “Where should I invest more resources?” or “How can I combat idle time?”. Very vague and even open questions, such as “How can I improve this process?” can now be answered for the first time.

Use The Cloud Instead Of Your Infrastructure

The ability to access previously unused data and use it using machine learning is one of the drivers of Industry 4.0. Fortunately, companies no longer need their infrastructure to store and evaluate the data. You can collect the cloud computing provider AWS data and use it directly there. Thus, you can benefit from the massive potential of machine learning without your own expensive data centers.

More and more companies are already creating data lakes on AWS in which they aggregate all data – with or without structure. While they may not have a use for this data today, it is ready for tomorrow’s ML-based innovations.

Manufacturers should be aware that they should have already taken two steps on their digitization journey for data lakes and ML: the cloud migration of their IT and the networking of the machines. Once these milestones have been taken, and the data lake takes shape, the next step is to ensure data quality.

The Basis For Success: Well-Curated Data

Machine learning needs a clean foundation of data. The data must be available in digital form and, at the same time, be complete and free of errors. After all, algorithms can only reliably recognize and predict what they have been taught beforehand.

Nobody is currently spared the process of curating and preparing the data. If data is not adequately prepared, the data scientists will have to spend a lot of time curating it. It is then not uncommon for 80 percent of the project effort to go into data preparation alone. Unfortunately, no algorithm can help here because the measure depends on the quality and properly annotated data. In this context, it is also essential to define responsibilities for the data: A data owner is therefore required, the keyword “data governance.”

Using Data Made Easy

When the cloud migration is complete, all machines are connected, and a data lake with high data quality is available, ML solutions can be integrated. But many companies lack data scientists for this. Therefore, companies should take a look at end-to-end solutions.

AWS has recognized this need and offers – customer-centric as always – ML solutions in “low-code/no-code” approaches that map various industrial use cases. This means ML solutions can be introduced quickly, and data scientists’ need decreases. AWS now has several services on offer, into which their practical expertise from many projects has flowed. This is the case, for example, with object recognition.

Quality Management With Machine Vision

Amazon Lookout for Vision is a no/low-code solution for computer vision-based anomaly detection in image and video data. The ML service helps identify and prevent errors and problems in product manufacturing. In particular, quality management processes can be accelerated, and previously manual inspection processes can be automated. In addition to defects in materials or surfaces, missing components, for example, in assemblies, can also be identified.

The Highlight: Lookout for Vision is exceptionally user-friendly and can also be set up by employees who have no training as data scientists. Images are first uploaded to a GUI designed for this purpose or via API. With some Lookout for Vision services, you can start with just 30 appearances. The user can then indicate which images show good or bad quality. The model is then automatically trained with this input. The otherwise time-consuming decision as to which the service takes over parameters and which algorithms are most suitable. This also includes the integration of data pipelines and the transformation of the data. Although this is a bit more expensive, the use of a data scientist can often be avoided, and the expert is free for more complex tasks.

When Lookout for Vision is live, detected anomalies are displayed in a clear dashboard, and the production manager can react quickly. Last but not least: The service is fully managed, so maintenance and upgrades are automatically covered. And as new versions are developed, seamless integration occurs.

Step By Step To The Goal

Depending on the status of digitization, the path to ML solutions in production is shorter or longer. Many companies are also taking a break or giving up, as evidenced by the countless canceled ML and data projects and proofs of concept. There are a few milestones to be reached: cloud migration, machine networking, data lakes with good data quality, and then the integration of ML services.

Where and how do you start? An African proverb says: If you want to go fast, go alone. If you’re going to go far, go together. The same applies here: companies with reliable partners can accelerate their digitization journey enormously and even gain ground over competitors who started earlier but lost momentum without external expertise.