3 Tips to work safely with industrial robot

Safety in industrial robotics is paramount. Manufacturers have a responsibility to protect workers from injury or harm, including ensuring compliance with standards and increased productivity in the process of improving safety.

For this, security mechanisms must be established to ensure that human operators can safely override unwanted behaviors of robots.

The installation of industrial robots requires safety measures, a costly and time-consuming exercise. Collaborative robots may offer a solution; however, these systems only meet safety standards if they operate at reduced speeds.

What are the potential risks when working with industrial robots?

There are several types of accidents that can occur when working with industrial robots. These include:

- Impact or collision accidents resulting from unpredictable movements, component malfunctions, or unpredictable program changes, related to the robot arm or peripheral equipment.

- Accidents due to crushing and entrapment of workers limbs or other body parts caught between a robot arm and other peripheral equipment, or that the worker can be physically driven and crushed by other peripheral equipment.

- Mechanical part accidents resulting from the failure of components for the robot drive, tooling or end effector, peripheral equipment or its power source. These include, for example, shifting of parts, failure of a gripping mechanism, or failure of end-effector power tools (for example, grinding wheels, polishing wheels, deburring tools, electric screwdrivers, and screwdrivers). nuts).

- Also, accidents can occur due to leaks in high pressure lines, arc flashes, metal splashes, dust, electromagnetic or radio frequency interference.

Hazard identification in industrial robotic systems can be one of the most important steps in assessing safety risks. Hazards can come in mechanical, electrical, thermal, noise, vibration, radiation, material, or ergonomic forms.

Why do accidents happen in industrial robotics?

Given the significant risk of accidents occurring, it is essential to understand why these incidents occur. Ultimately, these problems often stem from human error, control errors, unauthorized access, mechanical failure, environmental sources, power systems, and improper installations.

By far the most common cause is human error . Workers feel safe with the equipment and adapt to the hazards of working in unsafe areas when programming or maintaining a robot.

On the other hand, the problem can come from a programming error introduced by man or an error in the connection of the equipment. Other hazards can result from improper installation, lack of proper equipment maintenance, and malfunctioning hydraulic and electrical systems.

Industrial robots are capable of powerful movements over a large area, even beyond the base of the unit. Changes in materials or the environment can affect the programmed movements of the robot.

The use of physical barriers often protect workers from the dangers of industrial robots. However, accidents do happen.

3 Tips to prevent risks and improve safety in industrial robotics.

Identifying the causes of hazards in industrial robotics is a critical step and not always an easy consideration. Once hazards are identified and robotic interaction scenarios established, safety risk assessment is simplified.

The type of hazard that arises depends on your application, and is just as dependent when interacting with industrial robots, such as during integration, as well as during training and routine production or maintenance.

The circumstances of the interaction, along with the types of hazards, must be evaluated in relation to the types of industrial robotics safety protocols in place to prevent injury or harm to workers. Let’s see 3 tips that can help us to work safely with industrial robots:

1. Assessment of safety risks in industrial robotics

A risk assessment is the critical first step in industrial robotics safety that companies must perform to protect employees.

Industrial employers must ensure that workers understand and recognize these dangers of working with robots. To begin with, even before a company uses any robot, it is essential to carry out a risk assessment during the design phase of the robot.

At this point, the physical and operational limitations of the industrial robot, its purpose and its use (or misuse) must be identified. Next, any reasonably foreseeable hazards and hazardous safety conditions that may arise should be noted.

An important consideration is the human interaction during the life cycle of the machine and the possible states of the machine.

The goal is to eliminate as many identified hazards as possible. Then, through the risk assessment process, determine the appropriate type of functional safety controls to implement in industrial robotics to reduce risk to an acceptable level.

2. Minimize the risk of danger in industrial robotics

The information gathered during the risk assessment determines the type of equipment and controls used for the security monitoring system.

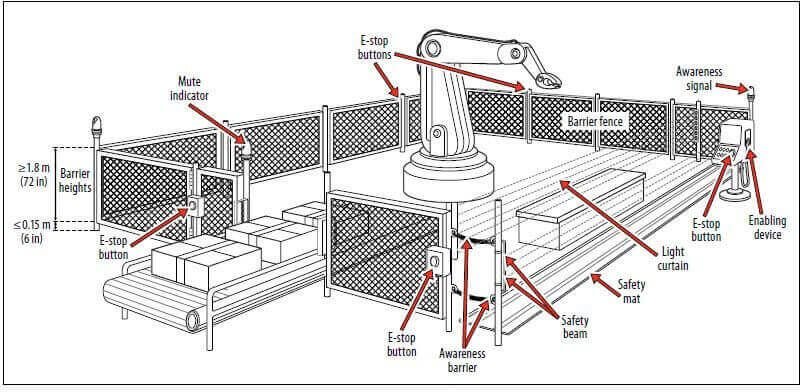

Engineering controls are used to restrict access to a danger zone. They can include the control of reliable electromechanical door locks, fixed barriers, two-hand control systems and presence detection devices such as light curtains, laser scanners in an area or pressure mats, etc.

These devices reduce the probability of exposure to the hazard (ie harm) but do not reduce the potential severity of the injury. Industrial controls are often the least favored preventive safety measures in industrial robotics, because they remain human dependent and only have the potential to reduce the probability of harm.

These controls include awareness devices such as signs, audible alarms, and visual warning lights to alert workers to the hazard. They also include procedures (operation and maintenance) and training.

3. Training in occupational safety and risk prevention in industrial robotics

It is vital for workers who program, work, maintain or repair industrial robots to receive adequate technical training in safety matters in order to be aware of the risk inherent in the activity. Consequently, they must be able to demonstrate their competence to perform their jobs safely.

Employers must provide their workers with personal protective equipment (PPE) and ensure that their employees use the protections properly. Good training in this field can help minimize damage in an accident. PPE includes protections such as respirators, gloves, face shields, hearing protection, hard hats, and safety glasses that workers must wear as the last layer of defense against injury. So they must know how they work and how they are used.

Conclusions

Rapid advances in technology have brought many types of physical robotic systems into the workplace.

Industrial robots now paint, weld, push, pull, lift and assemble products, while collaborative or collaborative robots, by having one or more mechanical arms, provide workers with an extra set of hands. They also help doctors perform complex surgical tasks.

Assessing the risks of industrial robotics is the first step in achieving robotic safety in a factory. Therefore, a proper assessment of the risks of working with industrial robots usually includes two steps: a risk analysis and a risk assessment.

A hazard analysis can be the more complicated of the two processes and often requires three different steps: determining the limits of robotic machinery, identifying potential safety hazards involved in production, and estimating the risk of identified hazards in working with robotics. industrial robotics.