a computerized maintenance management system (CMMS)?

A computerized maintenance management system or CMMS is software that centralizes maintenance information and facilitates maintenance operations processes. It helps optimize the use and availability of physical equipment such as vehicles, machinery, communications, plant infrastructure, and other assets. CMMS systems, also known as CMMIS or computerized maintenance management information system , are found in manufacturing, oil and gas production, power generation, construction, transportation, and other industries where physical infrastructure is fundamental.

The core of a CMMS is its database . It has a data model that organizes information about the assets that a maintenance organization is responsible for maintaining, as well as the equipment, materials, and other resources to do so.

What is a CMMS?

CMMS, short for computerized maintenance management system, is software that helps manage assets, schedule maintenance, and track work orders

How does a CMMS work?

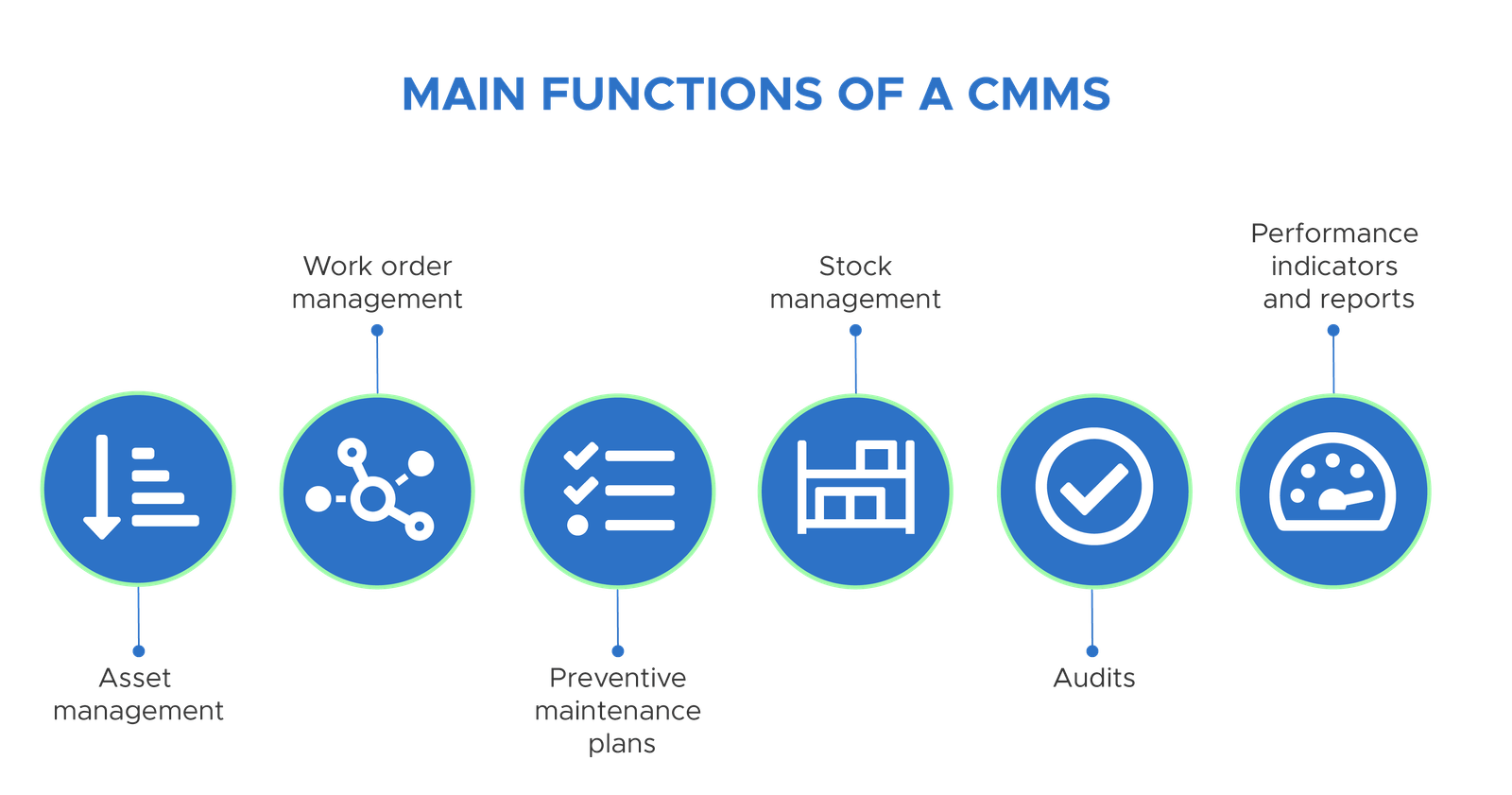

The information that resides in a CMMS database supports various system functions, enabling the following capabilities:

Resource and workforce management: Track available employees and equipment certifications. Assign specific tasks and form work teams. Organize shifts and manage pay rates.

Asset Registry – Store, access, and share asset information such as:

- Manufacturer, model, serial number and category and type of equipment

- Associated costs and codes

- location and position

- Performance and downtime statistics

- Related documentation, videos, and images, such as repair manuals, safety procedures, and warranties

Availability of meters, sensors and instrumentation of the Internet of Things (IoT)

Work order management: Considered the core function of the CMMS, work order management includes information such as:

- work order number

- Description and priority

- Type of order (repair, replacement, programming)

- Cause and remedy codes

- Assigned personnel and materials used

Work order management also includes resources for:

- Automate the generation of work orders

- Reserve materials and equipment

- Schedule and assign employees, work teams and shifts

- Review status and track downtime

- Record actual and estimated costs

- Attach documentation, means of repair and associated security measures

Preventive Maintenance – Automate work order initiation based on time, usage, or triggered events. Use preventive maintenance to organize and associate assets in multiple orders. Sequence and schedule preventative work orders.

Inventory and Materials Management: Inventory, distribute, and reuse maintenance, repair, and operations (MRO) equipment and materials in storage areas, distribution centers, and facilities. Manage vendors, track inventory costs, and automate replenishment.

Reporting, Analysis, and Auditing – Report on various maintenance categories such as asset availability, material usage, labor and material costs, vendor evaluations, and more. Analyze information to understand asset availability, performance trends, and MRO inventory optimization and other information to support business decisions and collect and organize information for audits¹.

The CMS story

Before CMMS, gaining dynamic, centralized visibility and automated management was unfeasible because maintenance information was hidden in paper files and later scattered across spreadsheets.

The first versions of CMMS appeared in the 1960s and were used by large companies. Technicians used punch cards and IBM mainframes to report to computerized logs and track maintenance tasks. In the 1970s, punch cards gave way to checklists entered into CMMS systems by technicians at the end of their shifts.

In the 1980s and 1990s, CMMS gained popularity among small and medium-sized businesses as computers became smaller, more accessible, more distributed, and more connected. In the 1990s, CMMS began to share information over local area networks, or LANs.

The 2000s saw the rise of intranets and web-based connectivity that expanded CMMS functionality to a variety of mobile devices, field applications, and operational sites.

The latest generation of CMMS is cloud-based and highly mobile. It offers increased functionality with faster deployment, easier maintenance, and better data security².

EAM vs. CMMS: What’s the Difference?

The term CMMS is often confused or used interchangeably with EAM or enterprise asset management. Both share very similar functions and objectives, but are essentially different. To distinguish the key differences between CMMS and EAM, it is helpful to briefly review the history of CMMS and the relationship between CMMS, EAM, and APM .

As CMMS have evolved, they have established a foundation for EAM. Basically, EAM contains the functionality of CMMS³, and their functions can overlap. What EAM brings to CMMS, thanks in part to increased connectivity and information sharing, is the ability to span sites, foster cross-department collaboration, and offer tighter integration with other systems such as enterprise resource planning (ERP) ⁴.

These features provide EAM solutions with a broader business context that considers the overall asset lifecycle and its impact on financial analysis, procurement, process management, risk and compliance, asset disposal and more. CMMS solutions tend to focus on fixed asset availability and uptime by automating orders and workflows, labor planning, materials management, and providing reports and audits on those tasks. .

Why is uptime so important?

Both CMMS and EAM are critical because they allow maintenance managers and departments to more easily and efficiently meet their primary goal: reliable uptime.

The longer physical assets and equipment are kept in operation, the greater the value they deliver. In her post, ” The complete guide to the benefits of CMMS ,” Sarah Dudley, blog editor at IBM notes, “The longer we can keep a computer running without major repairs, the more money we save in the long run.”

Delivering reliable uptime means businesses can accept and fulfill orders, meet customer demands, shape customer experiences, and make a variety of asset-based decisions with confidence. A survey of asset managers conducted by IBM found that 75% cite system reliability as the main reason for investing in EAM.

What are the benefits of a CMMS?

Visibility on assets: centralized information in a CMMS database allows maintenance managers and teams to request almost immediately knowledge of when an asset was purchased, when maintenance was performed, the frequency of breakdowns, the parts used, efficiency evaluations and more.

Workflow visibility: Dashboards and visualizations can be adjusted by technician and other team members to assess status and progress virtually in real time. Maintenance teams can quickly find out where an asset is, what it needs, who needs to work on it, and when.

Automation – Automating manual tasks such as ordering parts, replenishing MRO inventory, scheduling shifts, compiling information for audits, and other administrative tasks helps save time, reduce errors, improve productivity, and focus teams on maintenance tasks. non-administrative maintenance.

Streamlined processes: work orders can be viewed and tracked by all parties involved. Details can be shared between mobile devices to coordinate on-site work with operations centers. In addition, both the distribution and the use of materials and resources can be prioritized and optimized.

Field Workforce Management: Managing both internal and external workforces can be complex and costly. CMMS and EAM resources can cost-effectively unify and implement internal teams and external partnerships. The latest EAM solutions offer advancements in connectivity, mobility, augmented reality, and blockchain to transform operations in the field.

Preventive Maintenance – CMMS data enables maintenance operations to move from a reactive to a proactive approach, so an advanced asset maintenance strategy can be developed . Data from daily activities, as well as sensors, gauges, and other IoT instruments, can provide insight into processes and assets, inform preventative measures, and trigger alerts before assets fail or underperform. the expected.

Consistency and knowledge transfer: Documentation, repair manuals and media that capture maintenance procedures can be stored in the CMMS and associated with the corresponding assets. Collecting and maintaining this information creates consistent procedures and workforce. It also ensures that knowledge is transferred to new technicians, rather than disappearing with departing staff.

Compliance Management – Compliance audits can cause disruption to maintenance operations and asset-intensive businesses. CMMS data greatly facilitates audits by generating responses and reports tailored to audit demands.

Health, Safety and Environment: In accordance with compliance management, CMMS and EAM provide centralized reporting for safety, health and environment issues. The goals are to reduce risk and maintain a safe operating environment. CMMS and EAM can assist investigations with recurring incident or defect analysis, incident and corrective action traceability, and process change management.

Considerations for choosing CMMS software

Choosing and implementing an effective CMMS requires considering functional and technological factors. Providers and consumers may use the terms CMMS and EAM interchangeably in this context, which is acceptable due to the overlap in their resources.

One of the critical functional considerations, according to IDC IT Analyst , is managing increasing amounts of data: “As the number of data sources available to the asset manager continues to grow (sensors, spatial data, visual data , etc.), managing, merging, and analyzing these data pools will quickly become a tremendous challenge for EAM professionals in the next five years.”

IDC also notes that aligning staff and development resources with asset management can be critically important: “The function is often under resourced in terms of people, training, and development. This lack of resources lowers motivation and creates counterproductive staff culture.

Finally, IDC states that modernization of CMMS and EAM functions is important and that “some organizations have to leave behind legacy systems and spreadsheets for critical EAM functions such as repair order management, scheduling of work and replacement/repair decisions.

The push to SaaS

CMMS and EAM solutions address functional challenges in a variety of ways, but one of the key technology focuses is to implement cloud-hosted CMMS and EAM solutions as software as a service (SaaS).

According to IBM, “When choosing asset management software, companies are increasingly turning to software as a service (SaaS): a cloud-based delivery model in which software is centrally hosted by a supplier and available on demand”.

SaaS, as a technology approach, addresses a few main functional factors:

- Hosted in the cloud, SaaS CMMS offers the flexibility to scale and contract based on data demands. Users benefit by only paying for the data resources they need, rather than making large upfront investments to ensure the ability to handle the growing data stream of IoT instrumentation, virtually eliminating hardware costs.

- SaaS can help solve staffing and resource challenges, requiring far less IT intervention and support than on-premises implementations. CMMS engineers, CMMS administrators, and technical teams in the field can largely manage the system on their own. As a result, IT-related capital expenses can be converted into operational expenses and resources.

- Legacy systems, modernization, and using the latest technologies to keep up with maintenance and operational pressures are also areas where SaaS can help. Updates are performed by cloud service providers, so the latest versions and features are always applied. In addition, SaaS also integrates new technologies faster and with less risk. According to IBM , it “enables companies to try new approaches and solutions for their asset-intensive businesses, as well as discover new insights and operating models to gain competitive advantage.”