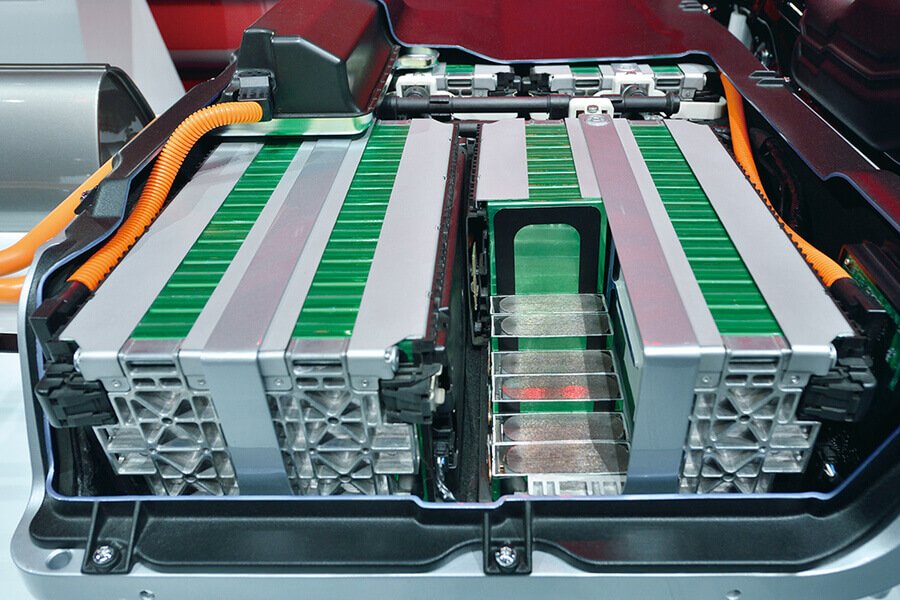

New advances in battery technology for electric vehicles

Battery technologies are fundamental to EVs. These technologies have become more sophisticated in recent years, providing greater performance to electric vehicles.

Electric vehicles: Towards a future without emissions.

Transportation is the second largest emitter of greenhouse gases, behind the energy industry. Addressing this problem and reducing the industry’s impact on climate change is one of the main concerns of researchers, industry bodies and governments around the world.

In the past decade, the global market for electric vehicles has taken a significant leap, and growing consumer demand for low-emission vehicles has fueled the evolution of the industry. Although the global COVID-19 pandemic has disrupted the auto industry to some extent, the growth of electric vehicle sales has remained positive.

Meeting global net-zero emissions targets is an important part of this EV revolution, as many countries aim to eliminate the sale of ICE vehicles entirely within the next few decades. However, electric vehicles continue to pose significant issues, such as range, battery performance and sustainability.

Improved battery technologies.

The race to improve electric vehicle batteries has been likened to a new gold rush. The development of battery technologies that provide EVs with greater autonomy, faster charging times and better performance, reliability and safety is one of the main research focuses of the sector.

In recent years, researchers and automakers have reported several exciting developments that will help the EV industry meet consumer demands and concerns. Although there are still many challenges ahead, it is essential to push the transport sector towards a post-carbon model.

A hybrid battery for fast-charging electric vehicles that will be revolutionary.

One of the main concerns currently hindering the widespread adoption of EV technologies by consumers is their charging time. Although progress has been made in reducing charging times, which until recently were several hours, current commercial models cannot compete with internal combustion vehicles in this regard.

Charging a battery in less time than it takes to refuel an internal combustion engine vehicle would be a revolutionary advance in battery technology that could greatly increase consumer acceptance of these vehicles.

Morand, a Swiss start-up, has introduced innovative battery technology that reduces the charging time of electric vehicles to about 72 seconds. The company’s innovative EV battery is a hybrid system using conventional and ultracapacitor battery technologies.

The technology, called e Technology, provides an 80% charge in 72 seconds and can charge an electric vehicle to 100% in just 2.5 minutes. Although it can’t meet the demands of long-range electric vehicles, the technology is ideal for small city cars, electric bikes, and drones. The technology also works effectively in extreme temperatures.

Improving the safety of lithium-ion batteries.

Safety is one of the main concerns of manufacturers of batteries for electric vehicles. Although rare, lithium ion batteries can catch fire, especially if damaged. Every year, companies spend large amounts of money developing and testing safer batteries that are not at risk of igniting.

Researchers at Stanford University have developed an electrolyte that is flame retardant even at extreme temperatures of more than 60ºC. The solution is to add lithium salt to the electrolytes. The team added lithium salt (specifically LiFSI) to a polymer-based electrolyte.

The lithium salt content of the electrolyte dropped from less than half to 63% by weight. In effect, the LiFSI acts as an “anchor” in the electrolyte for highly flammable solvent molecules. Thanks to this innovative solution, lithium-ion batteries can continue to function at temperatures of up to 100ºC.

Revealing the elusive interphase chemistry with X-rays.

Scientists from the US Department of Energy have provided new insights into the chemistry of the interface. The interface of a battery is crucial to improve energy density. The interface forms between the electrolyte and the anode when the battery is subjected to charge and discharge cycles.

The researchers published an in-depth study in Nature Nanotechnology on the solid-electrolyte interface in lithium-ion batteries, revealing its convoluted chemistry.

The team’s innovative approach took advantage of a unique combination of advanced X-ray techniques to provide an unprecedentedly detailed chemical map of interface components. The research revealed intimate details of the interface chemistry that will help future scientists design improved interfaces in lithium metal batteries.

Other new developments.

In recent years, scientists have explored multiple research angles to improve battery design and associated technology for electric vehicles, providing innovative solutions to several key industry challenges.

NAWA technologies have designed a revolutionary ultra-fast carbon nanotube electrode that significantly increases the power, energy storage and cycle life of batteries. Researchers at Chalmers University of Technology have focused on incorporating batteries as structural elements, which could reduce the weight of electric vehicles.

The University of Texas has studied batteries without cobalt, which overcome the problems of scarcity of resources of this critical metal. Finnish researchers have developed batteries with silicon anodes. IBM collaborates with Mercedes-Benz in the development of batteries with materials extracted from seawater.

Solid-state, zinc-air, and sand batteries are currently being investigated, which could offer safety, performance, and sustainability improvements over current lithium-ion batteries on the market.

The future of the EV battery market.

The electric vehicle market is undergoing a revolution as it strives to meet consumer demand and the transportation industry’s net zero carbon emissions commitments. Multiple car manufacturers are introducing home and commercial models to meet these demands.

Groundbreaking research being conducted by multiple academic institutions, government agencies, and automakers into battery design is a key driver of this technological revolution. Although several significant challenges remain, the future of the electric vehicle industry looks increasingly positive.