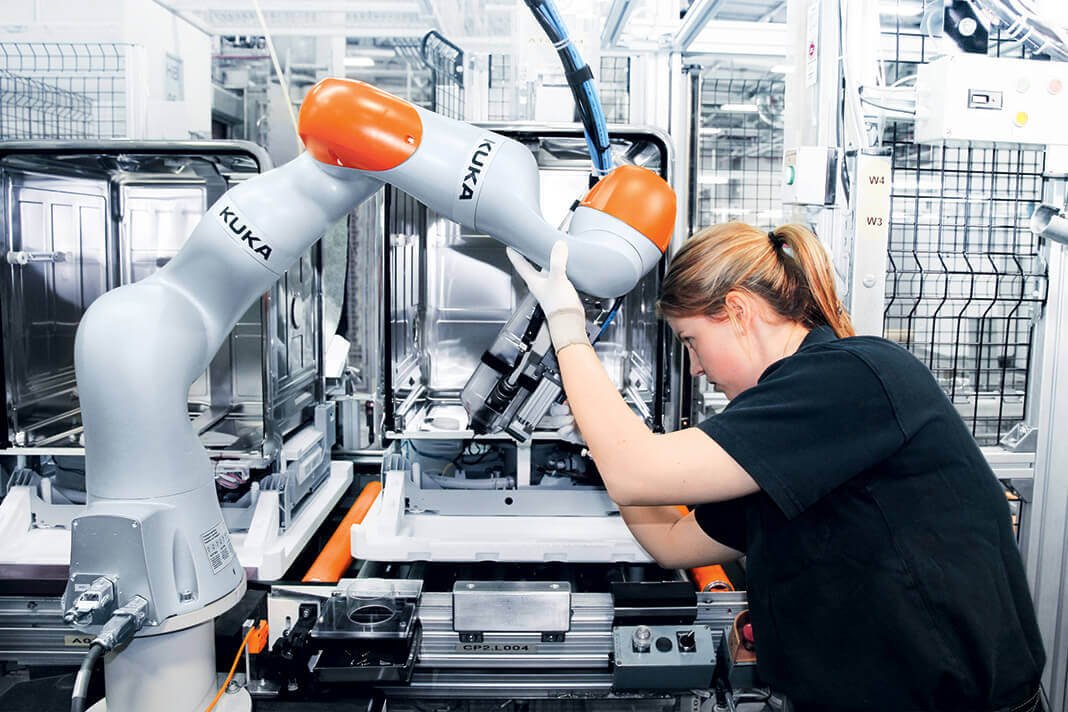

How robots can be used to improve workplace safety

Technological innovation, that is, the use of robotic systems in the workplace, has completely revolutionized the way companies operate. No longer concepts straight out of a science fiction movie, industrial robots have come a long way over the years, with applications that go beyond the automation of manufacturing and assembly line processes.

Today’s workplaces combine human and machine intelligence and take advantage of collaborative robots such as mobile robots, service robots, and autonomous robots to create safer working conditions.

According to the Bureau of Labor Statistics Survey of Occupational Injuries and Illnesses , employers reported 2.1 million nonfatal workplace injuries in 2020. In manufacturing facilities, chemical plants, and similar industrial settings, injuries are frequently caused by overexertion, slips and falls, exposure to harmful substances, and machine-related incidents.

From protecting worker health to addressing complacency, here are five ways robots can help improve workplace safety.

Contents

Handling of heavy objects

Built to handle physically intensive jobs, robots have the ability to lift and carry tremendously heavy objects. Manual lifting of large and bulky objects in the workplace exposes employees to increased risk of short- and long-term injuries, which could be detrimental to production and revenue goals.

Repeatedly picking up objects between 15 and 50 kg is dangerous for workers. Our robotic counterparts can handle more weight and move items faster, eliminating the safety risk this task poses to employees. Frequently performing this task leads to overexertion, poor posture, and a higher chance of permanent injury, such as spinal cord damage. Additionally, injuries related to overexertion, such as lifting, pushing, pulling, holding, carrying, or throwing objects, cost businesses more than $13.1 billion annually .

fighting fatigue

Both physical and mental fatigue can increase workplace injuries and accidents . Whether the culprit is monotonous, repetitive tasks or lack of sleep that workers struggle to overcome, employees are putting their safety at risk rather than stay home or navigate the proper channels internally for help.

As you may have guessed, robots do not require breaks, which makes them an effective solution to combat fatigue in the workplace. Certain types of robots have the ability to operate autonomously for hours, even days, without requiring attention. For robotic systems that require manual operation, the facility can strategically adjust workflow to ensure operators get in and out so processes can continue without interruption.

Protection against health risks

Despite following protocols and precautions, workers still face a high risk of developing potential health-related problems due to things like chemical exposure or other environmental factors, such as heat or toxic fumes. From manufacturing to the oil and gas industry, employees continually find themselves in harm’s way simply due to the hazardous nature of their environment and their day-to-day responsibilities. Working in dusty, toxin-filled conditions leaves your staff vulnerable to respiratory problems and even life-threatening diseases like lung cancer.

In the oil and gas industry, robots are being harnessed as a way to avoid sending employees into confined spaces like industrial storage tanks. Cleaning these compact, contaminated tanks with traditional means can present serious risks to the health and safety of workers. Robotic tank cleaning technology not only protects your team from hazardous working conditions, it can help drive efficiency and reduce cleaning-related costs by an estimated 20% to 25%.

Improved visibility

Using machine learning, artificial intelligence, and the Internet of Things, robotic systems can deliver robust analytics, providing valuable insights into everything from process inefficiencies to equipment maintenance needs. This information improves visibility, allowing leaders to make data-driven decisions and intercept problems before they escalate. The data collected can also be leveraged to introduce new processes or increase safety measures where necessary to prevent accidents and decrease injuries in the workplace.

disaster response

While the goal is to implement procedures intended to minimize accidents, if one does occur, robots serve as an effective tool to provide help and control in unexpected situations. From fighting oil refinery fires and controlling oil spills to removing heavy objects to free trapped workers, robots can be used to strengthen your company’s disaster response strategy.

The robots will continue to help

As technology continues to evolve, so will the breadth of capabilities offered by robots across industries. Employees deserve to work in an environment where safety initiatives are prioritized and they feel protected in the performance of their daily responsibilities. With the implementation of robotic systems on the rise, we can expect to see a corresponding improvement in workplace safety.